Hey friends! Something a little different today. A project with an extra layer of purpose, I suppose.

Recently, my little lady Stella has been gong through a kidney-related medical journey. It’s a long story, but she’s under a year and a half old and otherwise a healthy little bean, so finding something wrong with her kidneys was quite a surprise for all of us. We’re generally a once-a-year-checkup vet visit kind of family, and when we went I would throw a towel over the carrier to help them stay calm in the car and keep them from making accidental eye contact with a dog as we made our way into the vet’s office. Since this only happened once a year, the towel seemed fine (the towel IS fine) - but as they often do, priorities changed. Stella is starting off on a fairly frequent monitoring schedule where she’ll be having blood drawn every few months to see if we can identify any trends, and if/when that is established she’ll still be visiting the vet more than once a year.

The underlying current here is that kidney issues in cats are generally very bad news - we can manage symptoms to try and slow it down, and we think we’re early (still collecting more information on that) so all she needs to start with is a diet change and the monitoring - but knowing she has something that I can’t make all better the way I could if she had a sore tooth or an infection - is not my favourite feeling. So. When I tell you that I made a cover for the carrier to make it a better experience for her more frequent vet visits, that’s certainly a reason and it does do that job, but the particular level of engineering that went into this project was probably more related to the fact that it was something that I did actually have control over, in the midst of waiting for lab results and specialist opinions and treatment plans and all sorts of things I couldn’t.

If you’re here reading this post because you, too, have a medically complex friend you want to help with vet visits, I’ll share some of the other things we’re doing for Stella beyond the carrier cover at the end. but for now, let me tell you how I made (and how you too can make) the most over-engineered cat carrier cover you could possibly imagine!

The Carrier

This is our carrier - and honestly, I am mostly* a very big fan of it. It’s from Kmart NZ, it has a metal frame which collapses down so it can be stored flat(ish), and the fabric itself is waterproof. The fabric can also be removed from the frame which is super handy for cleaning. It has three access points - the top, one long side, and one short side - and the other two sides are just mesh windows. I like this because it provides our vet (and the cats) options, but it does present some complexities for covering compared to a standard hard-sided carrier with a single entry point. Similarly, the handles are spaced apart on the top like duffel bag handles, and although I find this more stable to carry than the small central handle on hard-sided carriers, it meant I had to come up with a way to make the cover removable (for washing) that also worked around those handles.

When I drape my towel over the carrier, I usually have the biggest fight with the handles as I try to keep all four sides covered. My towel is also longer, so when the carrier is placed on the floor while a cat is having their exam on the table, the towel is collecting vet’s-office-floor-grossness. Depending on which opening we want to use, it’s hard to keep the rest of the carrier covered - so these are the problems I’m aiming to solve.

*really the only thing I dislike is that the base isn’t stabilised - it feels a bit like a trampoline, and I know they’d prefer to be standing on something that felt a bit more solid. I have a few working ideas for this, but since the doors are too small to fit a sturdy piece of anything through, I’m still working on the best way to solve that particular problem

The Plan

A long, long time ago - before blogs and social media - I learned to sew in large part by making custom bags, carriers, and covers that had very specific purposes. This project really brought me back to the days of making custom carriers for all my art supplies in middle school!

There’s a lot of planning that needs to be done before we get to the sewing part to make sure we’re making something useful. Based on my carrier, I knew my main problems to solve would be working around the handles and providing access to all three doors. At this stage, looking at your carrier - what are the main problems you need to solve? How many doors does it have? Does it have a shape with curves that might be a bit more difficult to cover? Are there specific access points you need? Can you anticipate any issues at this stage that you’re likely to run into?

Once you have your list of problems, you can start in on solutions - and your first idea won’t always be the best one! I puzzled through the ‘handles’ problem on my carrier for a few days, and landed on what I initially thought was the perfect answer - I was going to create a long rectangular welt opening, and install a separating zipper with gaps at either side of the welt, so that the handle could be pulled through and the carrier zipped up. I was fully committed to this idea to the point where I even bought zippers when I got my fabric for this project! Eventually though, I came up with a MUCH simpler solution. Simpler to sew, to operate, and nicer looking too! It’s okay to change your mind about what the best solution is, but our goal here is to have everything lined up so that if we do change our mind about anything, we can anticipate how this might change additional construction steps down the line.

I like to do ‘solutions’ with a little sketch. I broke down my carrier into individual faces - top, short door, long door (plus the two non-door sides, not pictured - those didn’t need any solutions!) Then I can make a list of all the solutions for each part. At this stage, consult your list of ‘problems’ and make sure everything is addressed. Will addressing them create more problems, or require special steps? Here are some things that came up for me and might come up for you:

Closures: I chose magnetic snaps - I wanted the door flaps to be easy to access by a vet tech whose focus would be elsewhere, and also be easy to open and close quickly and ideally with one hand. This requires the flaps to have an overlap so the two halves can be snapped together.

Access: Speaking of easy to access, the openings needed to be visually different than the two non-opening sides so that someone unfamiliar with the carrier could still open them. Conversely, I like to put secret passport pockets in my purses and travel bags, for which the specific goal is that someone unfamiliar with the bag would have no idea there’s a pocket there, even if they’re looking directly at it. I decided to bias bind the flaps in grey to make them more obvious.

Staying Open: the carrier itself has velcro squares that can be used to hold the doors open, and I figured I’d want the doors of the cover to be held open in a similar way. Velcro isn’t my jam - it gets caught on my sweaters - but think about whether you’d like your door to stay open as well. Does holding it open change how it opens? Mine open from the top, but one that opens to the side could work as well if it was easier to secure!

Fit: I want my cover to fit very close to the carrier and not look saggy at all, but it is going to need to have some positive ease so it can slide on and off the carrier easily - especially since my cover is canvas so it has more resistance than, say, a hard plastic one. I’ll need to add a bit of ease to my pattern, but I’ll also add some structure to make sure it doesn’t sag. Double-layered cotton drill for the top part of the bag, and bias binding for the short sides to help them stand on their own.

Opacity: The point of the carrier is to block out light - is the fabric you’re planning to use thick enough for that? I used quilting cotton and cotton drill, but all my flaps have a second quilting cotton layer inside to darken things up a bit more.

Did you notice how each of those things I listed had the problem, a solution, and some thoughts on how I’d construct the cover to implement the solution? Things like bias binding, and overlapping the flaps so my magnets would fit. This sort of planning helps make the rest of the process much easier!

At this stage, you should have a list of all the super fun and useful bells and whistles your carrier will have, and some plans for how you’ll make those things happen!

Measuring and Drafting the Pattern

For this stage, you’ll need a ruler, a soft measuring tape, a pencil, paper, and of course - the carrier!

I like to work through projects like this by keeping them in their separate component parts (the sides and top of the carrier, in this example) until it’s absolutely unavoidable that they be connected. It’s simpler to work through the problems that way, and when sewing you want to make sure all the small pieces are done before you start connecting big things and making your project hard to manoeuvre!

The process is just about the same for each side of the carrier - take actual measurements, determine ease, and decide what pattern pieces you need for all the features. I started with the top - my most complex face - but also the one that’s fairly integral to the way the cover fits. I used the stitching lines on the carrier itself as a starting point for my pattern pieces.

At this stage, I still thought I was going to be using zippers. It wasn’t until I got to actually looking at the paper pieces that I realised how messy that was going to be, and how I could change my method for a much cleaner result! Doing all that planning in advance doesn’t mean you have to make the project that way - it allows you to change your mind about features confidently and helps you understand the domino effect that the changes might have on other areas of the project so you can anticipate future problems!

I started with the piece that covers each short end - marked out space (plus a bit of room for shifting) for the handles and added a bit of extra length to serve as ease. One of these ends (on the left, above) has an extra underlap area for the magnets to attach to the flap. Next, I drafted the long side pieces. Following the design of the carrier, this piece goes down over the curved side, and its upper edge comes just inside the handle. I added an extension to wrap around the handle, and drafted the top edge as close as I could get to the top flap zipper without potentially overlapping and causing the zipper to snag. Finally, I drafted the top flap cover. This attaches at one short end, and then overlaps with the other three pieces. I wanted to add sew-in magnets to keep the flap from shifting or gaping, so I made sure there was enough overlap to allow me to slip those in during construction.

These paper pieces functionally fit, but before you start cutting fabric it pays to think about how you’ll construct them. I wanted a clean edge finish (and inside finish!) so I decided to double layer everything. The flap will be bias bound, cut in a few layers for stability, and sandwiched between the double layer at the end.

Next up, the sides!

Again, same process. I start with my measurements, determine required ease, and draw out the shape. The short end includes a curved piece to fit over the top of the door. I measured reference points off the curved zipper to determine how much to cut out for the door - getting as close as I could to the zipper without getting so close that it would interfere with opening the carrier. I then re-drafted the shape of the door to include the overlap space I needed for my magnets.

I followed the same process for the long side with the door, and then the two non-opening sides were super easy! I didn’t want to leave them plain, so I traced off the full shape of each side (using the door sides I’d already drafted) as well as the original window shapes. These don’t have any functional requirements other than fit, so they’re super easy!

The last step would be to add seam allowances, but I will confess at this stage that I usually skip this step - over the years I’ve gotten pretty good at eyeballing a seam allowance! Depending on your confidence levels, you could choose to trace off your pattern and add seam allowances before you move on to cutting. I do generally write seam allowance notes and construction points on my pattern pieces.

Starting Construction: Sewing the Top

My fabrics of choice are a 100% cotton drill, and a cotton quilting cotton with a very cute cat-themed novelty print. I pre-washed both at high heat, anticipating the cover will need to be washed.

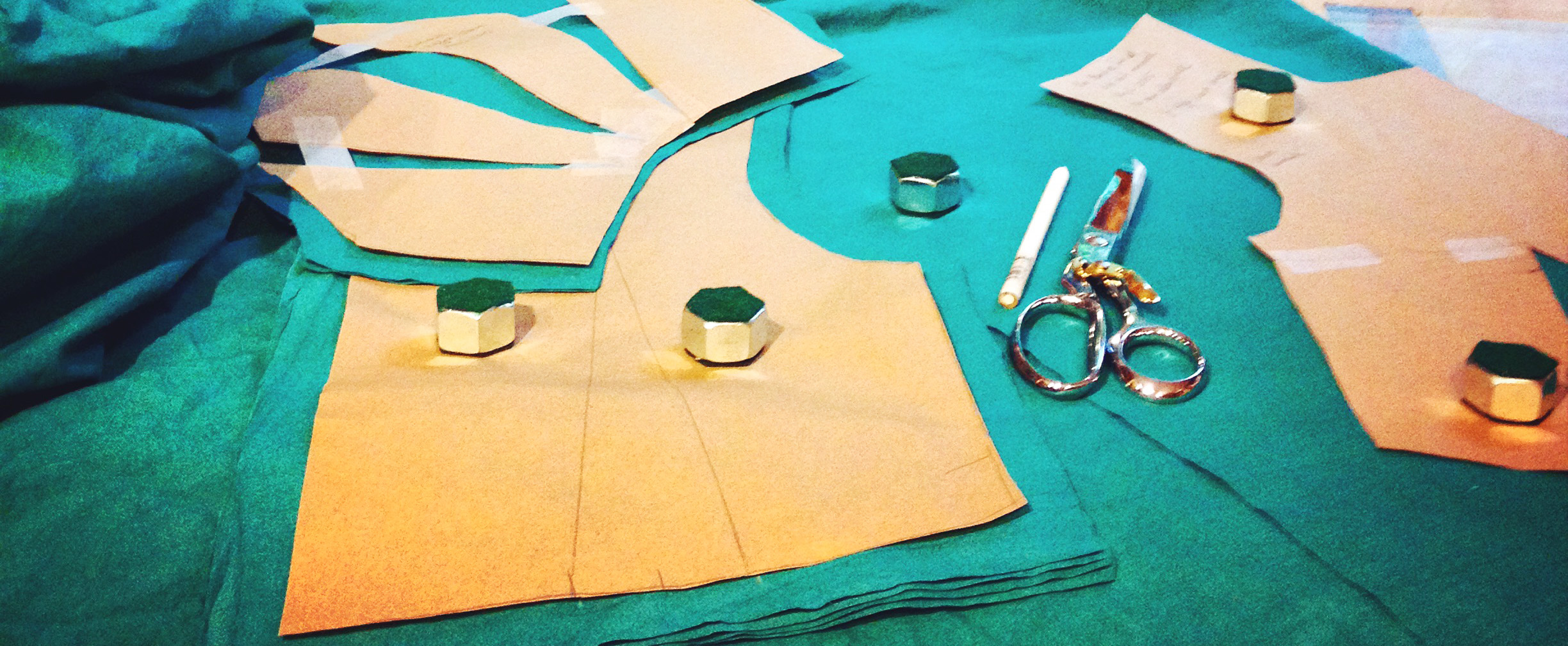

I worked on this project over about two weeks, so for sanity’s sake I continued to treat each side individually all the way through, including cutting and sewing. I cut and constructed the top entirely before moving on to the sides. Here are all the pattern pieces, cut and ready for assembly:

For that clean finish, there’s two of everything you see, and I also cut an additional internal layer for the flap as it was looking a bit too transparent!

I ran a few quilting lines through all three layers of the flap before adding the side magnets and bias binding the curved edge.

Sew-in magnets come encased in a flexible but tough plastic which extends beyond the edges of the magnet. In order to stitch these in safely, you want to make sure you’re stitching through that plastic border so the magnet can’t grow legs and wander off. They’re a bit of an adventure to sew with as they like to attach themselves to nearby metal (the throat plate of a sewing machine, for instance) and clips are best since the plastic is tough to pin through. If you work slowly and guide the magnet through when it tries to stick to things, you’ll be just fine! Next, I stitched all the opening edges right sides together, understitched where possible, and pressed everything into place.

The flap is sandwiched between two layers of one short side, and the short sides are connected under the handles to the long sides. Once the pieces were constructed, I used the placement of the sew-in magnets on the flap to position and topstitch their partners in place.

This is what the whole top piece looks like! The little tab pieces will get hardware (scroll down!) but before that, I did a quick test fit on the carrier to make sure everything was going according to plan. Stella took it through quite a rigorous approval process as well!

Sewing the Sides

The two sides with the doors follow much the same method as the top, except the underlap is a single piece instead of the four edges I was dealing with for the top. I cut each side out individually, constructed the flaps (again, three layers of fabric and bias bound) and cut two of each underlap curved piece so I could neatly finish the edge.

That edge is sewn right sides together, and understitched for stability, and again I used the magnet placement from the flap to set the magnets underneath.

The last two sides - the ones that don’t open - went so quickly I may or may not have completely forgotten to take a photo of them by themselves! They’re just the whole base piece with my fun kitty fabric sewn on as a patch: edges pressed under and topstitched! So speedy! Here are our pieces all laid out:

Assembling the Cover

Finally - the five sides come together to become one object! I stitched the long sides to the top with a flat felled seam, which meant I had a nice finish on both sides, and also added stability. Then, I attached the two short ends (the ones with the curved upper corners) and bias bound those seams as planned. The bulk of the bias binding helps the corners keep their shape, even though there’s about half an inch of dead space underneath each one.

At this stage, all I had left was the hem, but I came across one last problem I hadn’t accounted for when I did my test fit. the bottom edge of the cover flaps around a fair bit, as the positive ease I added to get the cover on and off easily meant that there was excess at the bottom edge. Not only was this going to be annoying, it was also going to affect how easy the snaps would be to manipulate. I couldn’t just take it in (I need the ease to get it on and off!). I considered a drawstring, but I wasn’t keen on having any strings hanging out!

After a bit of puzzling, I landed on a simple solution. I added elastic to each corner of the carrier, effectively cinching the corners in and keeping the flat sections taut against the corners. I encased the elastic inside a bias tape hem, and that was that! A constructed carrier! Here, you can see the elastic I added to each corner (about 3” of elastic per corner) and the resulting cinched corner, as modelled by Stella:

Installing Snap Hardware

Technically, I could’ve done some hardware installation before the final assembly, but I was waiting on my magnetic snaps to arrive so this is a bit out of order!

There are three types of closures on my cover (again, over-engineered!) - and also I really like adding hardware because my hardware press is fun to use! If you don’t have these bells and whistles - velcro, or snaps applied with snap pliers, or any manner of other fixture you can think of would work!

We already talked about the sew-in snaps I added to stop the flaps from gaping open. In addition to those, I used spring snaps for the handle tabs, and magnetic rivet snaps as the main flap closures. I chose two different types because I wanted them to look visually different so that someone unfamiliar with the cover wouldn’t try to un-snap a handle tab thinking it was a flap, but now having done it I’m actually not that sure if it was necessary - I think it’s pretty obvious which is which!

Snap components and dies for the small spring snaps

Components and dies for the magnetic rivet snaps

The spring snaps have four parts, and are applied with a set of four dies. The magnetic snaps are double capped - they use the same domed cap piece for both the plug and socket, so the die set is only three pieces. In each case, the installation process is the same.

First, I use my awl to poke a hole in the fabric where the snap should go (I did this while the carrier was “wearing” the cover, through all layers, to ensure things would line up correctly) - then, I push the shank of the lower piece through the fabric, place it on the press, add the corresponding part to the top of the press, and pull the lever!

I wrote a blog post a while ago on types of snap hardware - it was written mostly with baby clothes in mind, and before I had my snap press. At the time, I wasn’t sure if a snap press would be worth it, but obviously now having one has changed my mind!

I love this thing. I love not having to wait until a socially acceptable time to set my snaps (an activity that previously involved hammering), and I love not having to sit on the floor, or on the deck outside to do said hammering (my work table isn’t really sturdy enough for hardware). Also, there’s no risk of accidentally over-hammering, or setting a snap crooked if the tool is off-centre. It’s an added cost, and buying dies for every new snap type and size is probably the biggest negative factor, but I know what I like and I’ve just been buying them slowly as I need them, which works well. It’s also excellent on the wrists, compared to hammering or squeezing snap pliers, which is a bonus.

Anyways, that’s our finished carrier, in all her over-engineered glory, plus of course, the inside with its fun bias binding adding a pop of colour that Stella will absolutely not appreciate:

Making Vet Visits Less Stressful

Team, this post is already massive but I feel like I’ve committed now so we’re just going to keep going.

I haven’t taken Stella back for her next round of blood draws yet, so I haven’t had a chance to see whether the cover makes a difference to her stress levels. I have, however, taken Theo for his annual checkup and I actually was quite surprised at how much calmer he seemed in the car than on previous visits - a positive sign! The cover isn’t the only thing we’re doing for Stella to help her stay calm during her next visit though. Not everything on this list would work in every situation, but these are a few things I’ve learned as we’ve navigated Stella’s diagnosis, and I hope some of them at least might help you reading this, if you’re in a similar situation.

Carrier cover: I mentioned this project was “to make it a better experience” but I didn’t really say why - The flashing sunlight through the trees, rooftops and cars zipping past the windows, and the strange experience of moving in a vehicle are all really unfamiliar things, and cats in general tend not to love unfamiliar situations. They are also more sensitive to light than we are, so bright lights can be overwhelming. Covering the carrier for transport helps dull the crazy-wild visual sensations of the trip, which helps a lot of cats to stay calm. Test this concept with your cat though- I have some friends with cats who get carsick, and some prefer to be able to see out of a window. It’s easy enough to try a towel or a blanket first!

Feliway: We used the Feliway Friends diffuser to help reduce the tension of introducing Stella to our household when she was a kitten, but the Classic Feliway ( some places call it Feliway Calm) comes as both a spray and a diffuser and is meant to help reduce anxiety with pheromones. My plan is to spritz this on the inside of the carrier cover before her next visit. You’re meant to let it dry before they have a chance of coming into contact with it, so a spritz about half an hour before we leave should do the trick. It doesn’t work on all cats though! I spritzed some on one of their beds just to try it out, and Theo was the opposite of calm! He started trying to bury the bed with a nearby blanket! Best to test first.

Carrier and Car training: This has been amazing so far! I’ve made a desensitisation plan for Stella to help her become more familiar with the car, and provide some positive experiences associated with it. We’re practicing being zipped into the carrier, carried around in the carrier, going down to the car, starting the car, and taking very short and then increasingly long trips that all are handsomely rewarded with her favourite treats. The process is meant to help her become more familiar with these things in a positive context, and the idea is that if she understands what’s happening she should be less stressed as a result. I’m sure she’ll still be stressed, but our goal is a reduction in duration and intensity. There’s a LOT to this - more than this post has room for - but if you want to read more about it, here’s a good article to start with!

Fear Free: The specialist we took Stella to is an ISFM Gold-Certified Cat Friendly Clinic, which I will absolutely confess sounded like a marketing ploy to me when I first read it. As it happens, it’s actually quite a big undertaking to get the certification - clinics have to have a dedicated, separate cat waiting room (if they also treat dogs, the area has to be completely closed off), there’s a noise limit, raised platforms in waiting rooms so cat carriers aren’t set on the floor, and a minimum time set on appointments so that the cat has a chance to acclimate to the room quietly before the exam begins. The staff are taught techniques to further reduce stress in the way they handle the cat - like not forcing them out of the carrier and such, and a ‘Cat Advocate’ is available at all times to help coach the owner and provide tips on decreasing stress.

This google rabbit hole introduced me to the concept of fear-free training, which is basically more of that car and carrier desensitisation, except with experiences cats are likely to have at a clinic. Stella (rightfully) freaked out when they tried to take her blood pressure (the cuff squeezes! How is she to know it won’t squeeze her whole arm off?!) so I ordered a cheap blood pressure cuff to practice velcro-ing it on and off her arm at home - again, handsomely rewarded with treats. She’s started to get excited when she sees the BP cuff now, because she’s associating it with treats! The goal with all of these things is that her next visit won’t be immediately jam-packed with compounding stressors.

I briefly looked into finding a regular vet that was also certified, but unfortunately where I live, the driving time was nearly triple that of our regular vet. Instead, I’ll be asking our regular vet if we can schedule extra appointment time for acclimation, try to plan appointment times when the waiting room is less likely to be busy, and making sure that everything is rewarded with treats.

Gabapentin: This one is definitely not for everyone, but in some cases, gabapentin can be prescribed by a vet as an anxiety-reduction tool for a vet visit. Previously, I’d have said this seemed like overkill, but Stella had residual trauma from her last set of visits for about two and a half weeks before she was back to her normal self, and that was rough to experience for all of us - she didn’t want us to touch her at all, she spooked at the smallest noise, and she spent a lot of time hiding. Our vet suggested Gabapentin before our next visit as a result. I’ll continue to treat this as a last resort - we might get to a point where we don’t need it - but I’m happy to use it if it means we can avoid another traumatic experience. Like I said, we haven’t actually tried it yet, but it’s worth asking your vet about if any of this sounds like it could help.

Well! Now that I’ve written this whole entire novel - thank you for sticking with me to the end! I hope at least some of it was helpful. If you’ve got a carrier cover to make, good luck with your process, and good luck with your future vet visits <3